NON-EUCLIDEAN CASTING GEOMETRIES II

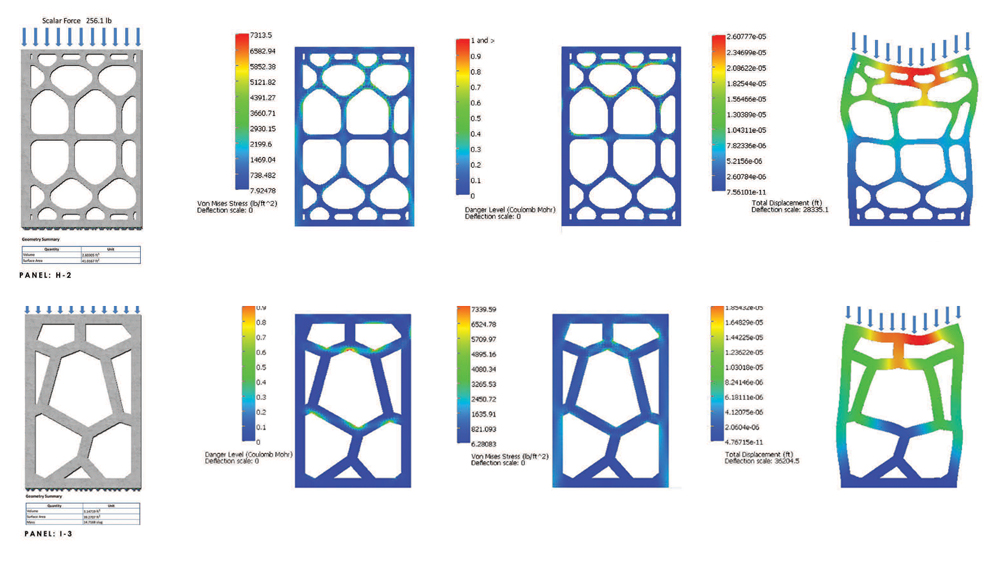

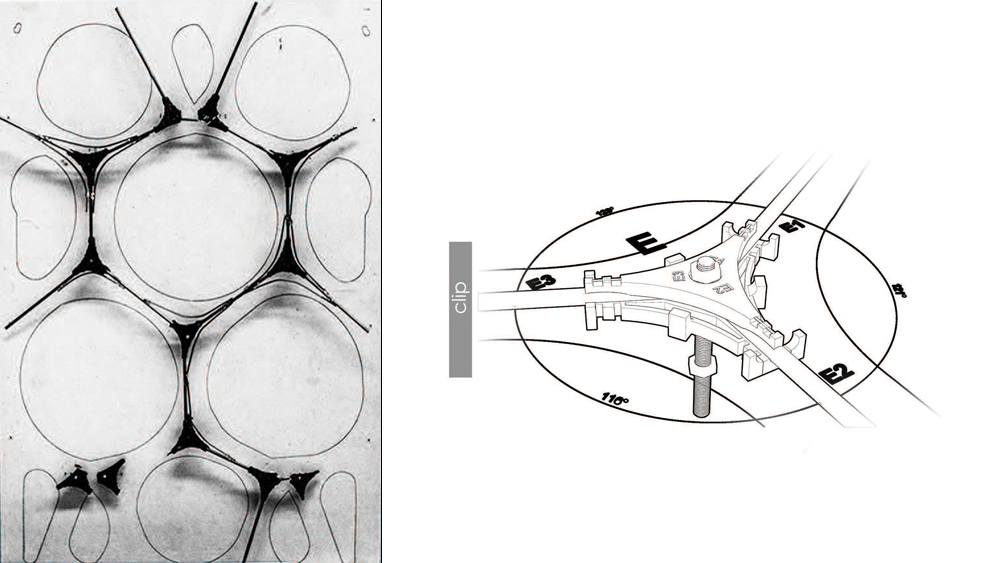

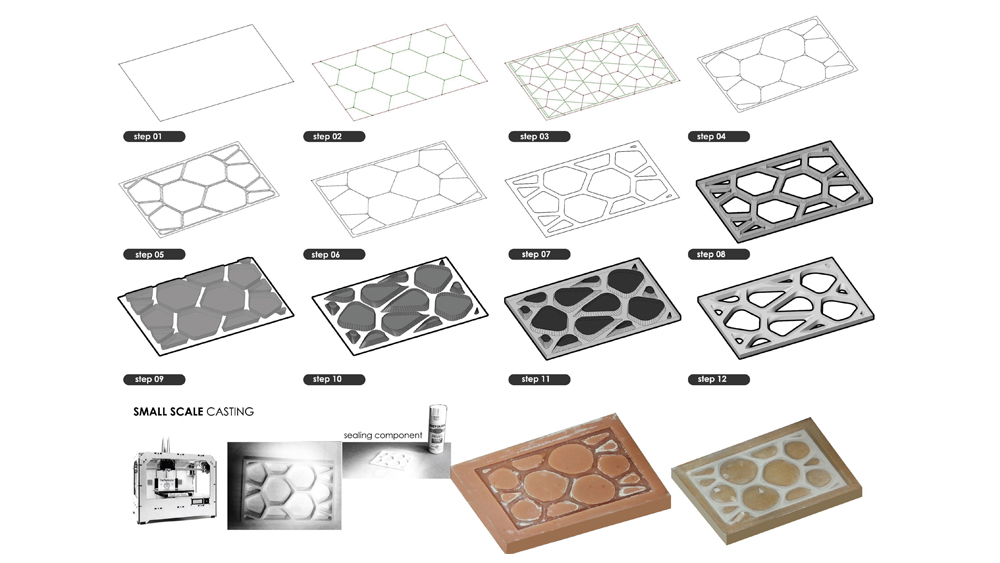

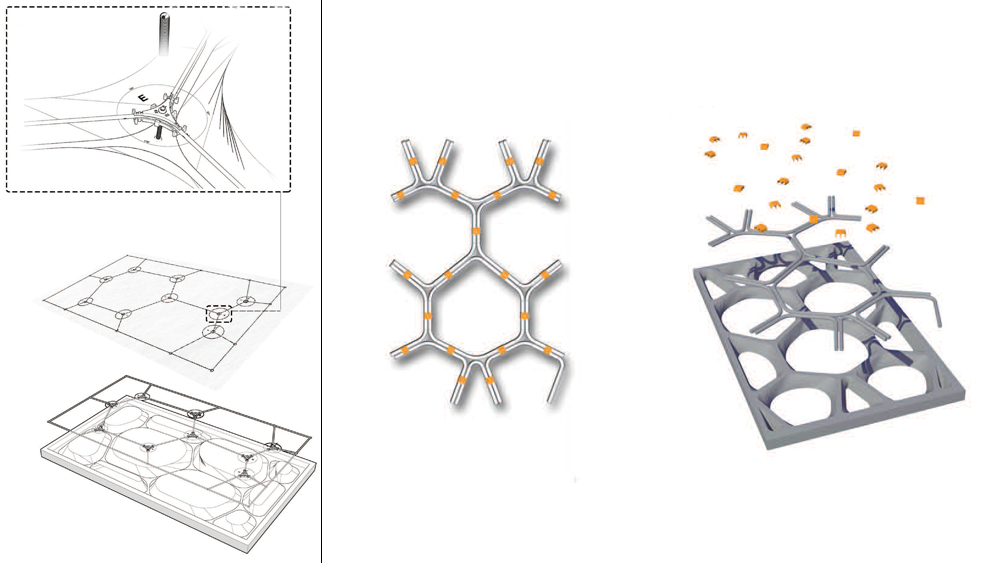

It has oftentimes been desirable to integrate porosity in concrete cladding systems to allow for conventional performance criteria such as light penetration, breathability, and thermal control. Unfortunately, incorporation of porous openings in concrete panels introduces increased tensile stress, a problem further compounded in complication when porosity is irregular. Traditional fabrication techniques currently limit the degree to which these openings can be deformed or arranged due in part to a lack of standardized methodologies for ordering steel reinforcement in non-linear arrays or grids. This is especially true in precast concrete panels where standardization of steel configuration and efficiency of implementation are key governing factors. In order to fabricate reinforced perforated panels with enhanced variability, it is then necessary to develop prescriptive code capable of procedurally ordering steel reinforcement such that it can as a consequence of digital analytics be arranged to compensate structurally for irregular perforation.

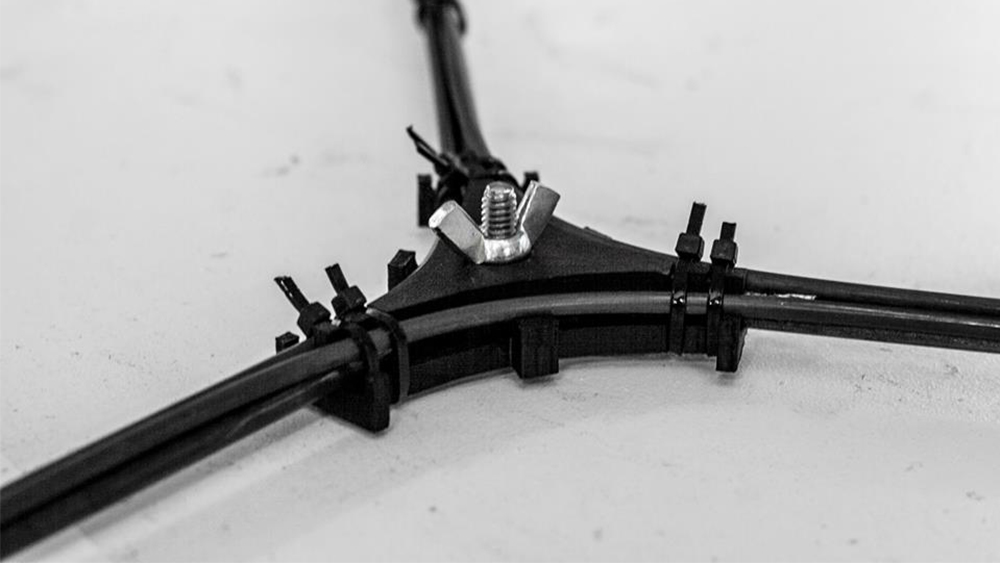

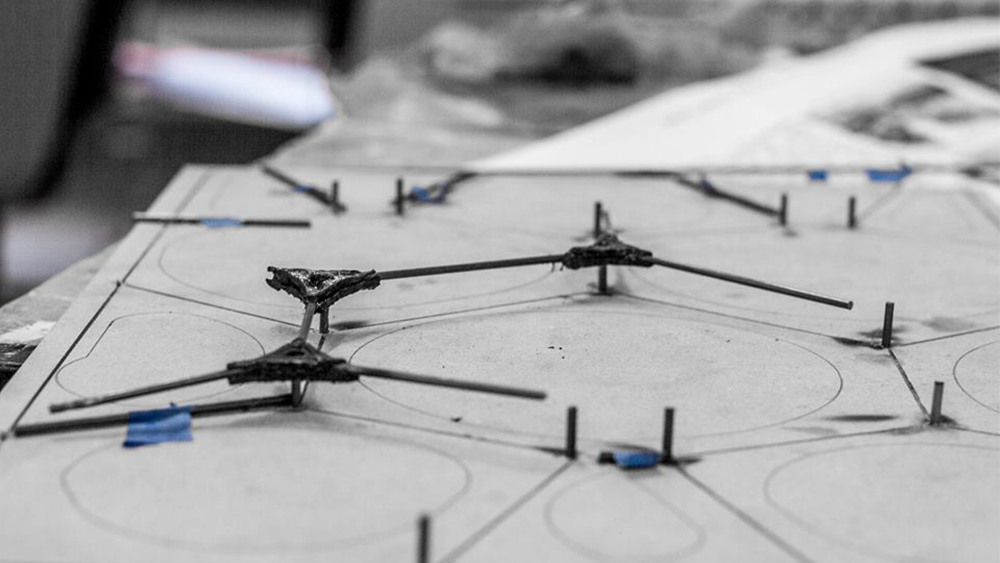

Necessary research criteria would include investigation of acceptable perforation typologies for integration, generation and evaluation of code both for control of porosity and ordering of steel reinforcement, development of standardized methodology for joining potentially irregular reinforcement assemblies, and fabrication of modularized formwork that can adapt to intense variation in both porosity and steel reinforcement. Research objectives must also consider and incorporate outcome in sustainability and conventional façade performance.

Team Members

Josh Hallett

Tenaj Pinder

Khang Nguyen

Related Projects

Non-Euclidean Casting Geometries I

Files

Non Euclidean Casting Geometries II PDF