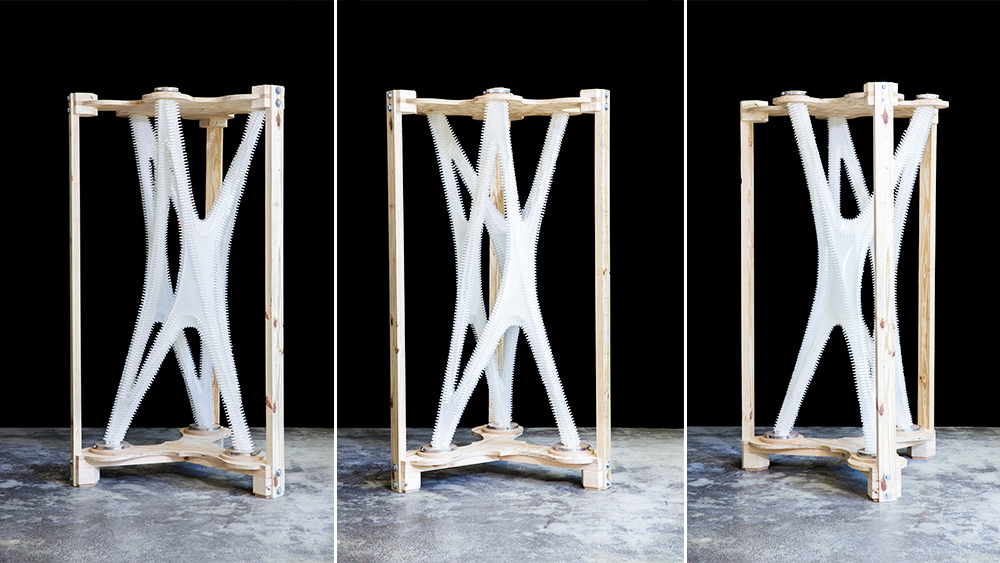

CAST COLUMNAR BRANCHING III

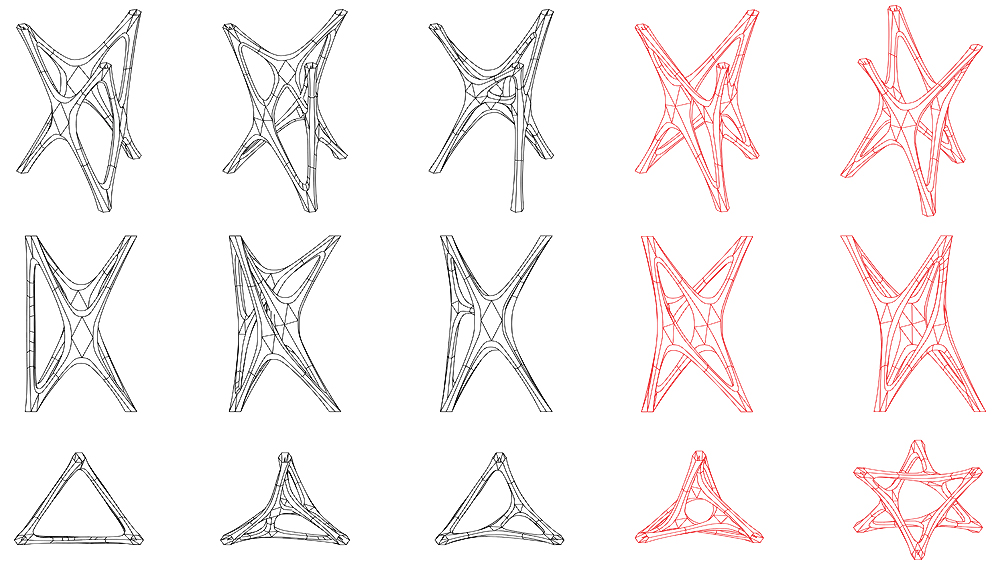

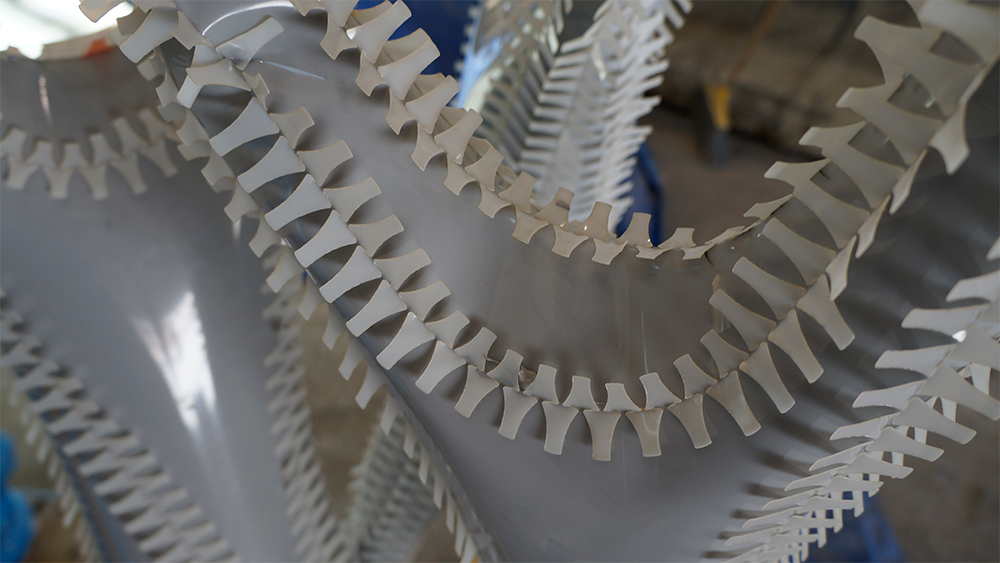

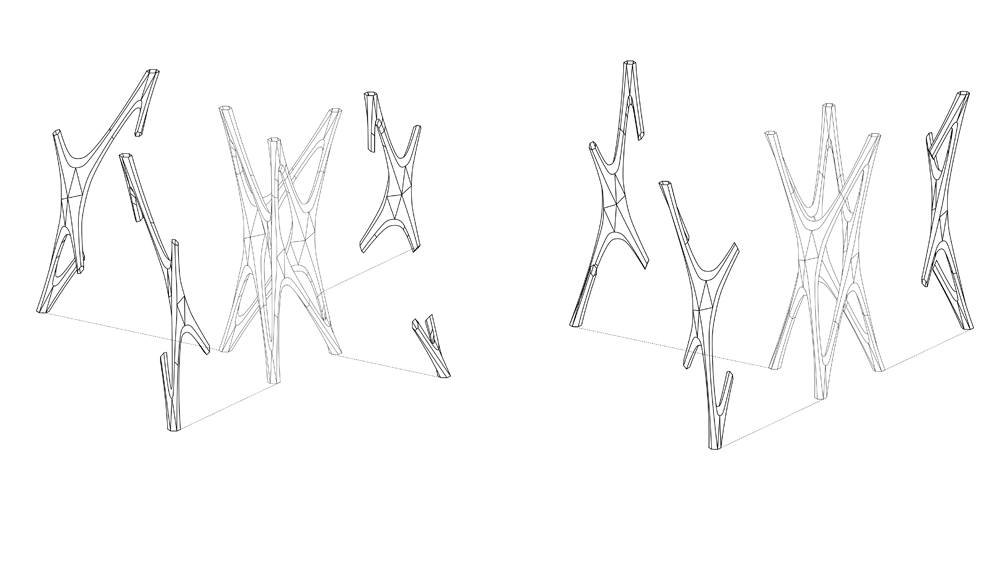

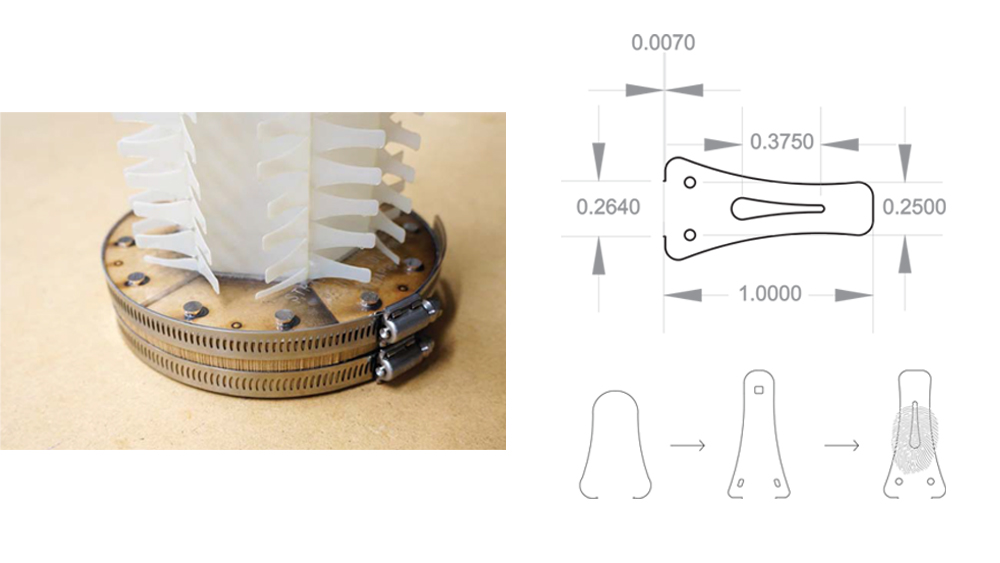

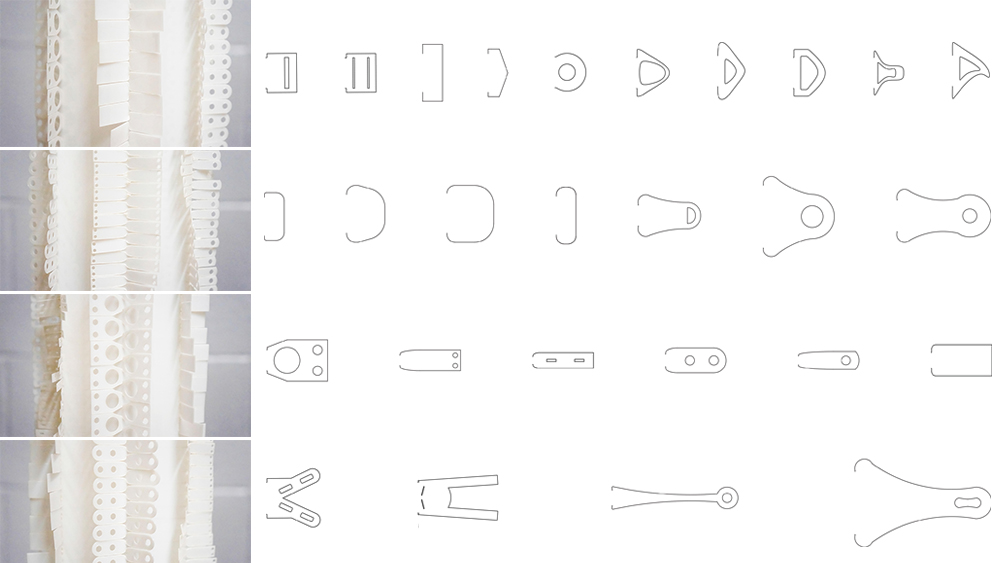

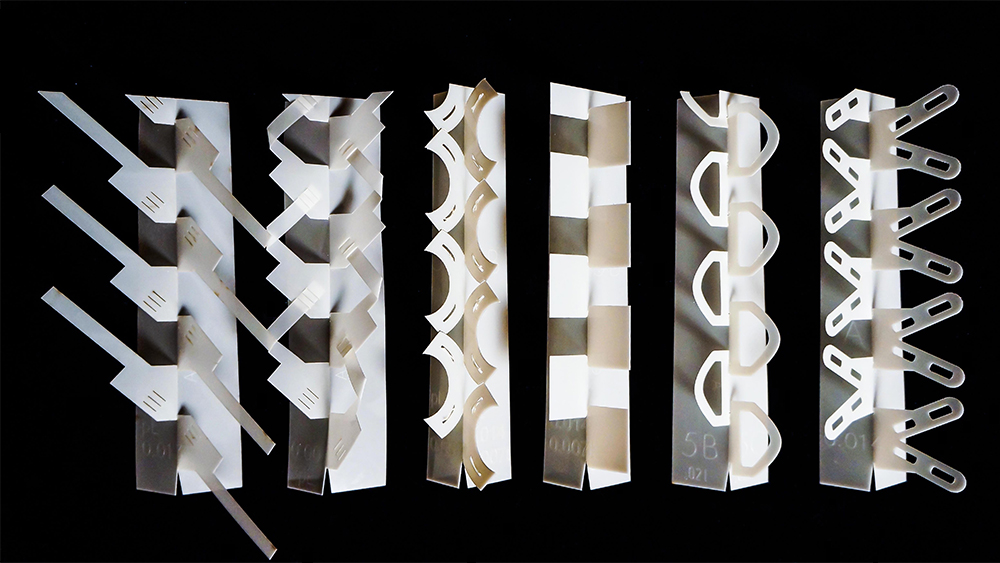

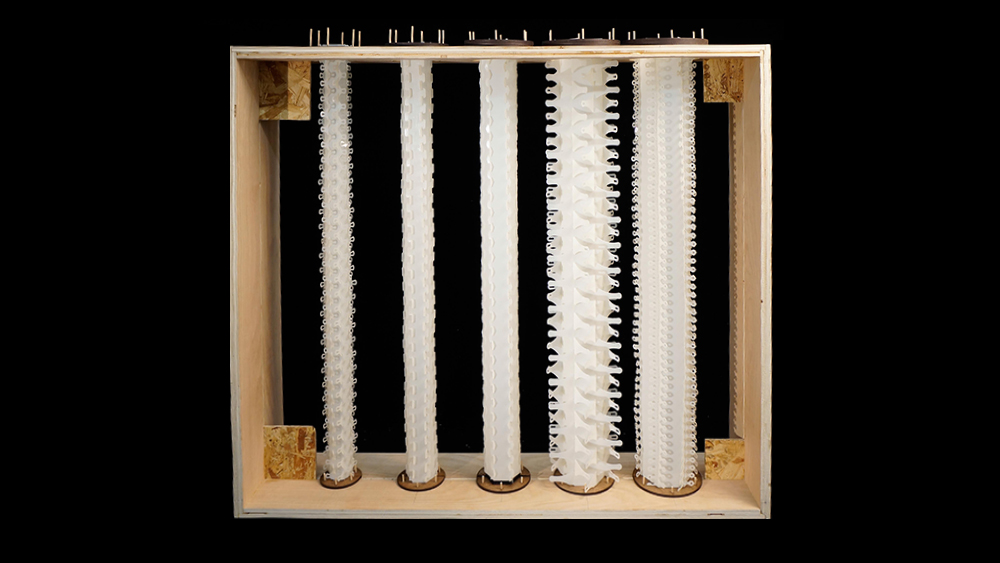

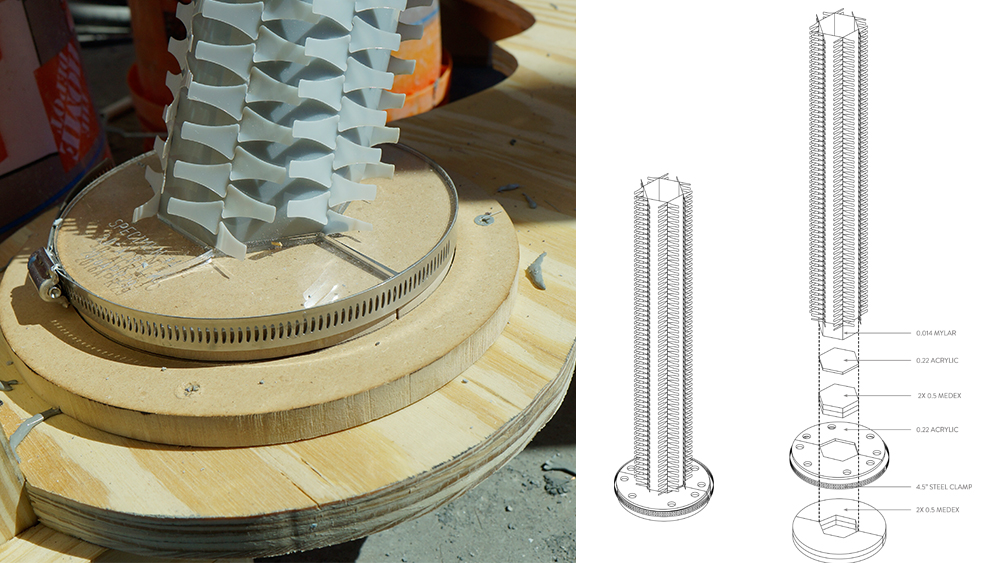

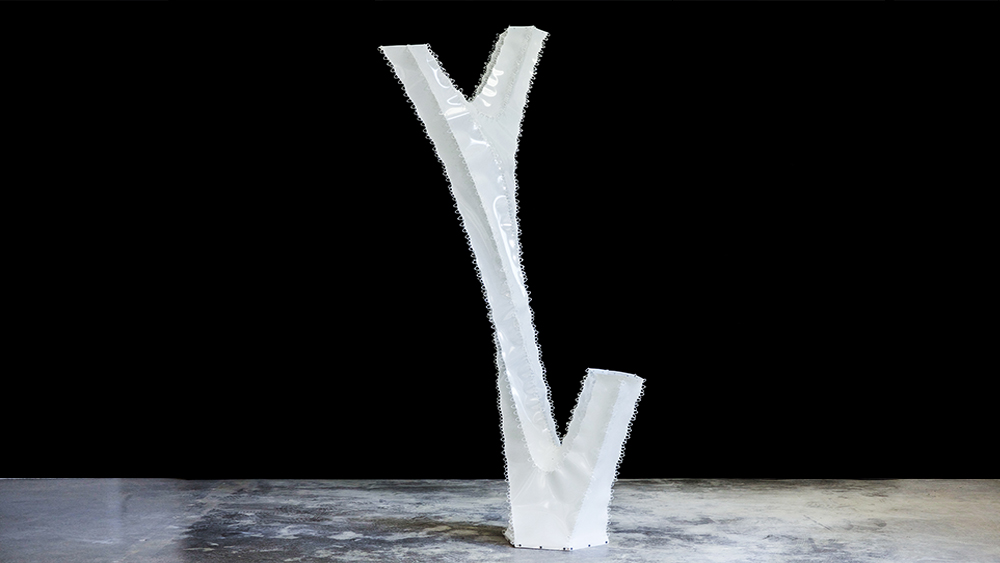

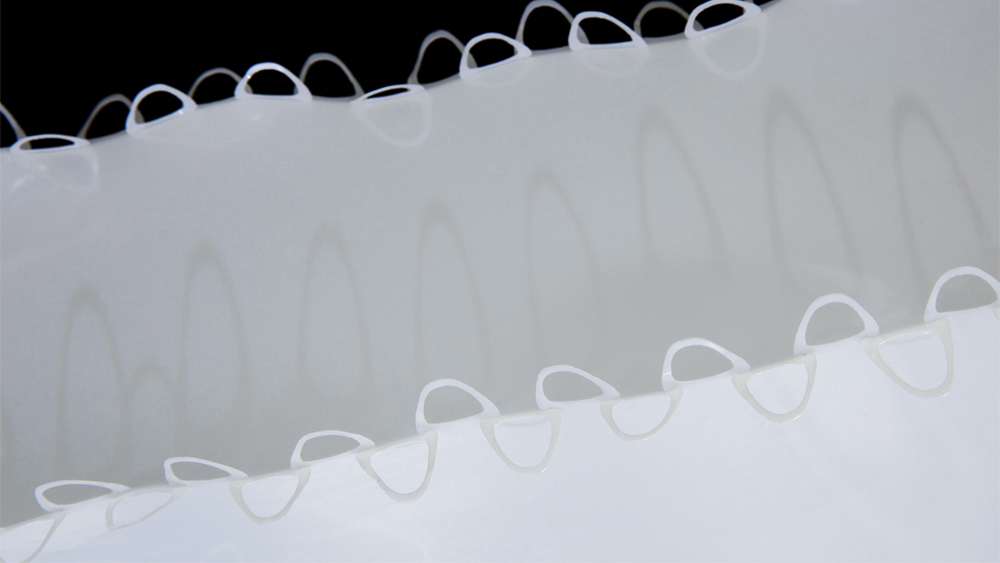

Cast Columnar Branching III is the third phase of research examining semi-rigid formwork to create asymmetrical columns. This work continues to examine the use of Ultra High Performance Reinforced Fiber Concrete (UHP-FRC) which makes it possible to provide no structural internal reinforcement. Specifically, the research concentrates on the refinement of the formwork material and the ‘zipper’ connection to provide a more efficient connection methodology. The ruled surface geometry combined with the hexagonal cross section is calibrated to match the structural material properties obtained in the testing performed in Cast Columnar Branching II. The size of the column members and the over-all height of the column form were derived by what the calculated structural load capacity would be during compression testing: 12kps. The two previous iterations of the research used polypropylene formwork. For this iteration, Mylar or polyethylene terephthalate film, was introduced for the material’s bi-axially configuration and high tensile strength of approximate 38,000 psi. By shifting to Mylar, laser cutting new tab profiles became the most feasible method for cutting the profile geometry out of the film. Testing for hydrostatic pressure, assembly sequence, length of cutting time were just some factors impacting the development and testing of the ‘zipper’ and material.

Team Members

Eric Enriquez

Christopher Laskoski

Bernabe Longoria

Industry Partners

Ken Tracy, Yo-Cy

Christine Yogiaman, Yo-Cy

Mark Tam, MIT

CELB UT Arlington

Dragon Laser

Related Projects

Cast Columnar Branching I

Files

Cast Columnar Branching III PDF